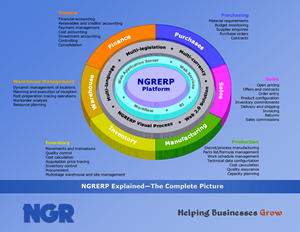

Inventory Management

At the heart of NGRERP is a robust inventory management system that provides complete control over all inventory-related activities for manufacturing and distribution companies. NGRERP contains powerful functionality for manufacturing and distribution organizations to improve inventory accuracy, inventory turn rates, and order and line item fill rates.

NGRERP's inventory management functionality includes paperless warehouse management, multiple inventory locations, flexible units of measure with automated conversions, physical inventory counts, cycle counts, and complete lot and serial number tracking. NGRERP's inventory management is fully-integrated with the entire NGRERP software suite.

Product Definition

In NGRERP, products can be defined across the entire business or on a facility-by-facility basis. Products can be associated with multi-level product grouping hierarchies for pricing, product management, planning, and reporting purposes. Inventory management rules can be defined either as simple minimum-maximum inventory reorder points, safety stock in days of supply, line item fill rate, or service level by product or by product-facility combination. Each product can have its own associated costing method, using either average, standard, LIFO, or FIFO costing.

Inventory Replenishment

NGRERP's inventory replenishment process analyzes supply and demand across multiple companies and facilities to help manufacturing and distribution organizations improve order and line item fill rates and optimize their overall inventory management performance. The inventory replenishment process considers a variety of criteria such as on-hand inventory, customer demand, and supplier lead times to calculate requirements and generate online requisitions, purchase orders, and inventory transfer requests. This process can be as automated as desired by manufacturing and distribution organizations requiring little or no manual interaction with the software.

Inventory Commitments and Allocations

NGRERP inventory management functionality manages inventory demand and assignment through the usage of inventory commitment and allocation. When sales orders are placed in NGRERP, available inventory can be committed to order line items. Then, as the date of order delivery approaches, the inventory allocation process ties specific physical inventory to order line items for warehouse pick, pack, and ship processing. The allocation process would also tie specific components, ingredients, and subassemblies to manufacturing work orders for production processing. NGRERP’s inventory management functional flexibility enables manufacturing and distribution organizations to define a series of business rules for inventory committing and allocation processing. Through this process, organizations can uniquely-define how they manage their inventories to provide outstanding customer service.

Multiple Units of Measure

NGRERP delivers a high-degree of flexibility in the management of product units of measure. Manufacturing and distribution organizations can define global and product-specific unit of measure conversions. On a product-by-product basis, default units of measure can be defined for various types of transactions. This allows manufacturers and distributors to sell, purchase, manufacture, receive, store, and ship in any unit of measure required.

Serial Number and Warranty Tracking

NGRERP's inventory management functionality provides complete serial number and warranty tracking. NGRERP tracks serial numbers and warranty periods for components, distributed items, and manufactured goods. The system also supports the consumption of serialized components in serialized finished goods. NGRERP automatically tracks whether items being serviced or returned are covered under warranty.

Lot Traceability

The NGRERP system provides complete lot tracking from receipt of inbound ingredient and component lots which are consumed in manufacturing and ultimately shipped out to customers. NGRERP supports both forward traceability from ingredients to customer shipments, and backward traceability from customer shipments, to manufactured lots, and finally to ingredient or component receipt from suppliers. In additional to lot number tracking, the lot tracking process also includes tracking of lots’ properties, grades, and testing results.

Attributed Inventory

NGRERP supports an unlimited number of product-based attributes for product definition and inventory management. These attributes may be a shoe’s color and width or an entry door’s wood species and component dimensions. Attributes can be used throughout NGRERP for sales order entry, pricing definition, requisition and work order generation, shipping, and invoicing.

Cycle Counts and Physical Inventories

NGRERP's inventory management functionality provides superior inventory control and accuracy for manufacturing and distribution organizations. NGRERP helps ensure inventory accuracy through the efficient management of the physical inventory and cycle count processes. In NGRERP, manufacturers and distributors can define their cycle count rules enabling the system to automatically generate recommended cycle counts. Physical inventory and cycle counts can be performed manually or with RF-enabled barcode scanners. Through the use of these physical inventory and cycle count processes, along with NGRERP's overall inventory management functionality, manufacturing and distribution organizations can improve overall inventory accuracy.

Catch Weight Processing

Catch weight processing is used by food processors and distributors to manage products where an individual item's actual weight varies. These products would typically be sold in one unit of measure such as packages or cases though priced by weight of the products shipped.

Material Safety Data Sheets

NGRERP supports the management of material safety data sheets (MSDS). In addition to storing the given MSDS by product, NGRERP can automatically print the MSDS for inclusion with the product shipment. Manufacturers and distributors can define their own MSDS rules that specify how frequently a given product’s MSDS is included with a shipment. NGRERP's MSDS management helps ensure organizations have the most current safety information readily available and provides a means of maintaining strict adherence to regulatory requirements.