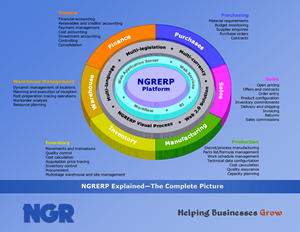

Inventory Replenishment

NGRERP's inventory replenishment process analyzes supply and demand across multiple companies and facilities to help manufacturing and distribution organizations improve order and line item fill rates and optimize their overall inventory management performance. The inventory replenishment process considers a variety of criteria such as on-hand inventory, customer demand, and supplier lead times to calculate requirements and generate online requisitions, purchase orders, and inventory transfer requests. This process can be as automated as desired by manufacturing and distribution organizations requiring little or no manual interaction with the software.

NGRERP's manufacturing requirements planning (MRP) and distribution requirements planning (DRP) processes compare available inventory with current and future demand to predict expected shortages over time. NGRERP also considers existing suppliers and their associated order requirements and lead times to produce online requisitions for review and conversion into purchase orders and inventory transfers. For manufacturing organizations, NGRERP’s MRP process also takes into account criteria such as bills of materials, routings, and production capacity to generate a tentative production schedule.

Unlike traditional manufacturing and distribution software packages, NGRERP provides more advanced processing capabilities by considering a given product’s desired safety stock, line item fill rate, and service level. These manufacturing and distribution software capabilities provide a more complete view of the inventory replenishment process, enabling greater inventory control and improved profitability.

Inventory Replenishment Highlights

- MRP and DRP processes evaluate key criteria to generate purchase requisitions and a tentative production schedule

- Supports review of purchase requisitions to generate purchase orders and inventory transfers

- Compares available inventory with current and future demand to predict expected inventory shortages over time

- Replenishment rules include minimum-maximum reorder point, safety stock levels, line item fill rate, and service level

- Supports approved suppliers, contract terms, blanket orders, and contracted purchase amounts

- Accounts for vendor lead times and order requirements

- Demand consists of customer orders and forecast which can reflect seasonal business trends