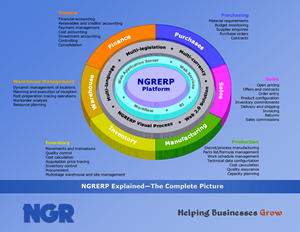

Manufacturing Management

NGRERP's manufacturing management software functionality supports process, discrete, and mixed-mode manufacturers engaged in make-to-stock, make-to-order, assemble-to-order, configure-to-order, and repetitive manufacturing processes. The NGRERP system provides superior functionality for managing advancing planning, production scheduling, material requirements planning, and production reporting.

Additionally, distribution organizations can leverage NGRERP’s kitting and assembly functionality to manage their internal and outsourced manufacturing requirements to deliver superior value-added services to their customers.

NGRERP's manufacturing management software functionality provides a flexible solution to meet a variety of manufacturing environments and associated industry compliance requirements. NGRERP delivers improved order fill rates while reducing manufacturing and inventory carrying costs. This is accomplished through NGRERP's fully-integrated manufacturing planning and scheduling functionality, streamlined production reporting, and robust quality control processing.

The NGRERP software suite delivers the end-to-end functionality required by process and discrete manufacturers, including manufacturing, inventory, warehouse, order, procurement, and financial management in a complete, fully-integrated software solution.

Bill of Materials

At the heart of product definition for produced items in the NGRERP system are bills of material (BOM's). BOM's are primarily used for discrete manufacturing, assembly, and kitting processes in NGRERP. BOM's can have infinite levels and include pseudos, subassemblies, and phantoms. Through the engineering change processes in NGRERP, BOM's can go through version revisions. NGRERP includes where-used functionality for visibility to where specific components and subassemblies are used across all products, enabling rapid mass change processing.

Formulas and Recipes

NGRERP's process manufacturing software functionality supports complete formula and recipe management. Multi-level formulas can include ingredients, intermediates, and other formulas. Through the engineering change processes in NGRERP, formulas can go through version revisions. NGRERP's where-used functionality provides complete visibility to specific ingredients, intermediates, and formulas which are used in the production of multiple products. Through the integration of formulas and associated processing instructions and notes, process manufacturers can create recipes which are used during batch process production.

Scalable Batches

NGRERP's process manufacturing software functionality supports the management of scalable batches. Companies can establish formulas and recipes with associated routings for batch production at defined standard batch sizes. Assuming a process manufacturer’s operations require variable batch size production, NGRERP can scale the associated ingredients and intermediates in the formula to support the desired scalable batch size.

Routing Maintenance

In conjunction with bills of materials for discrete manufacturers and formulas and recipes for process manufacturers, NGRERP's manufacturing software functionality uses routings to help manage the entire production process. Routings consist of a series of steps which define the sequenced processes and work centers a given product must go through for its production.

Engineering Change Orders

NGRERP's manufacturing software functionality includes complete engineering change order (ECO) processing for discrete and process manufacturers. Through the ECO process, a new version or revision of a given product’s bill of materials (BOM) or formula can be created. In NGRERP, the given engineering change can be routed through the organization for online review and approval for the promotion of a proposed BOM or formula to an active status. The new version of the BOM or formula would be used in material requirements planning (MRP), production scheduling, production recording, and for updated product costing. A similar engineering change process is used for the revision of production routings.

Kitting and Assembly

NGRERP software supports kitting and assembly processes for manufacturing and distribution organizations. Kitting can be performed through a picking process or as a manufacturing process where associated labor and burden are also collected for accurate costing purposes.

In NGRERP, kitting and assembly processes use the establishment of an infinite-level bill of materials. Manufactured kits and assemblies also use associated routings. In the NGRERP system, organizations can establish the schedule for manufactured kits and assemblies through the production planning or MRP process.

Production Reporting

NGRERP's production reporting and shop floor control functionality offers discrete and process manufacturers the ability to record real-time labor and production data. Production reporting can be performed by employees in a variety of manners, including data entry with keyboards and touch-screen devices and scanning from tether-attached, handheld, and forklift-mounted devices. NGRERP's production reporting and shop floor control capabilities enable efficient data entry and organization-wide access to production data, supporting inventory management, customer service, financial management, and costing processes.

Good Manufacturing Practices

Good Manufacturing Practices (GMP) refers to an organization’s ability to ensure that products are consistently produced and controlled to appropriate quality standards in the production of foods, pharmaceutical products, and medical devices. GMP covers all aspects of the manufacturing process, product storage and transport, serial number tracking, and lot traceability.

Machine Maintenance

NGRERP's machine maintenance software functionality provides the ability to track machine maintenance intervals and be notified when a given machine requires maintenance. Maintenance management allows for the establishment of machine component lists and associated mean-time between failure (MTBF) standards, creation of standardized procedure lists, and the association of procedures and maintenance documents to specific machines and processes. NGRERP's production scheduling and maintenance management functionality are fully integrated, thus allowing for time to be reserved on the production schedule for preventative maintenance activities. In addition, plant floor personnel can immediately initiate machine maintenance in the event of machine anomalies and downtime.